Latest Performance Data:

-

Current proven on-time delivery performance: 100%

-

Current proven quality performance: 100%

A reputation for cutting edge, precision engineering.

Groveley manufactures precision engineered components for ‘safety critical’ equipment. As one of the UK’s leading companies in its field, Groveley specialises in turning, milling, grinding and finishing a wide range of materials, namely:

- Stainless steels

- Titanium

- Ferrous, non-ferrous metals and plastics

- Friction materials

Latest News

JOB OPPORTUNITY – CNC TURNER

AS9100 Rev D External Audit Results

From Raw Material to Treatments

JOB OPPORTUNITY – CNC Miller

Challenge Us!

If you have a project in mind, why not send over the details.

Go on, challenge our expertise!

A reputation based upon experience and the highest of standards.

With over 50 years of experience within the precision engineering industry, we are proud of our enviable reputation as a flexible and efficient sub-contract engineering company, with an excellent track record and the highest standards of customer satisfaction.

Our markets include

A reputation based upon an ethos of continuous improvement.

With our recent SC21 accreditation, our position in the supply chain has been further strengthened. We are committed to a process centered approach to ensure we provide the best possible products and customer service.

Our promise to you

- Assured and proven on-time delivery.

- Confidence of consistent, exacting standards.

- Fully compliant to your requirements.

Innovation

The senior management's unrelenting pursuit of excellence and continuous improvement is endorsed by our on-going investment in the latest leading-edge equipment, and our highly skilled and dedicated workforce.

Machine capacity to service all of your requirements.

Groveley specialises in turning, milling, grinding and finishing a wide range of materials. With a programme of continual investment, Groveley has a range of state-of-the-art machine types to service all of your precision engineering requirements.

The turning centre range includes

- Puma TT1800 (CNC 9 axis twin spindle).

- Citizen L20 (CNC 10 axis dual spindle sliding headstock).

- Ajax Evolution 310–155 (CNC 2 axis horizontal lathe).

- Colchester Tornado (CNC 2 axis horizontal lathe).

The milling range includes

- Haas VF2YT (3+2 axis).

- Haas VFOE (3 axis).

- Cincinnati Arrow 500 (4 axis).

- Bridgeport VMC 600 22 (3 axis).

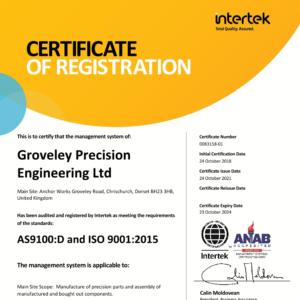

Quality Assured

It is Groveley's policy to supply products and services at a level of integrity that merits total customer satisfaction. To reflect the quality of our work, we have the following certifications:

- AS9100:REV D Aerospace Quality Management System

- ISO9001:2015 Quality Management System

- ISO14001:2015 Environmental Management System

- 2014/34/EU (ATEX) Directive

- SC21 Silver Award for 8 years

Quality Management

The senior management's unrelenting pursuit of excellence and continuous improvement is endorsed by our on-going investment in the latest leading-edge equipment, and our highly skilled and dedicated workforce.

Groveley’s senior management offers an effective and pro-active quality programme, ensuring consistent performance. We conduct regular management reviews to ensure we are reviewing objectives and targets and continually improving the effectiveness and performance of our Management System.

- Current proven on-time delivery performance 99.9%

- Quality performance 99.9%