From Raw Material to Treatments

A Complete Service from Raw Material to Treatments.

Groveley Precision has been machining complex parts for decades and our portfolio of parts is forever growing. Not only do we machine the parts from its raw material state, we also supply finished parts to our customers including treatments and fittings.

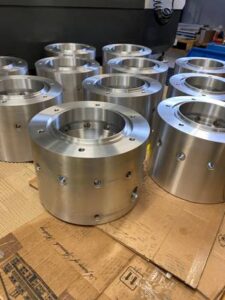

The images in this post are a perfect example of what we can achieve. The 300mm diameter x 220mm long billets have been turned, bored and set to a multi-axis mill to add the complex features including threaded hole details both internally & externally.

Post machining the parts are deburred, inspected, cleaned and then packed for treatments. In this case a Dichromate seal Anodize has been applied by one of our approved suppliers, of which protects the aluminium substrate as the part is subject to high temperature and pressure in its working environment.

On the parts return, the treatments are checked before the final stage of fitting threaded stainless steel thread inserts for long life thread retention.

As these parts are of high value, as well as large & heavy, we also provided be-spoke plywood packing cases, this protects them from any potentially damage whilst transiting for treatments and when being delivered to the customer.

Once again, one very happy customer received their valuable parts to drawing, specification and on time.

If you have new products, projects, want to resource existing work, are in a crisis situation or wish to mitigate risk. Tell us about your problem.